Abstract

A new, camera based color measurement technology combines the best of two worlds, object assessment and accurate color measurement. Measuring multiple areas in one cycle speeds up the process and adding user friendly software allows unskilled workers to operate it. In the detergent industry standardized stains are washed and the change of their color is a strong parameter which is used to improve the product and create new formulas. In the same way that a red wine stain is washed out of a white shirt back at home.

Traditionally instruments like spectrophotometers are used in labs to measure color. Although these instruments are accurate they are not the most user-friendly and they require skilled workers to operate them. In the detergent industry, a small wash test takes twenty different stains, two repetitions and two wash loads. Tested on four different detergent formulas gives a total of 320 color samples to measure, or even 640 if measured both before and after washing. A simple but time consuming job that, because of the accuracy required and technical nature of a spectrophotometer, can not be done by unskilled workers.

The Mach5 is a camera based instrument that can measure the color of various areas at the same time. These measurement areas can be rectangular, round or any other shape. The user sees a live image of the object and can use the mouse to position the measurement areas. The instrument measures absolute color and gives output in L*,a*,b* and X,Y,Z values. In the wash test mentioned above the Mach5 could measure

20 samples in one go so instead of 320, only 16 cycles of measurement are needed, speeding up the process and making it more user friendly. Data can easily be exported and if needed, users can even add their own Python script, for instance to automate their own (statistical) calculations, to combine, move or prepare data for custom reporting, etc…

Another issue is the nature of the work. Measuring 320 color samples one by one with a traditional spectrophotometer requires a lot of repetitions, both physical and mental. It is hard to find people who can repeat the same small job eight hours a day.

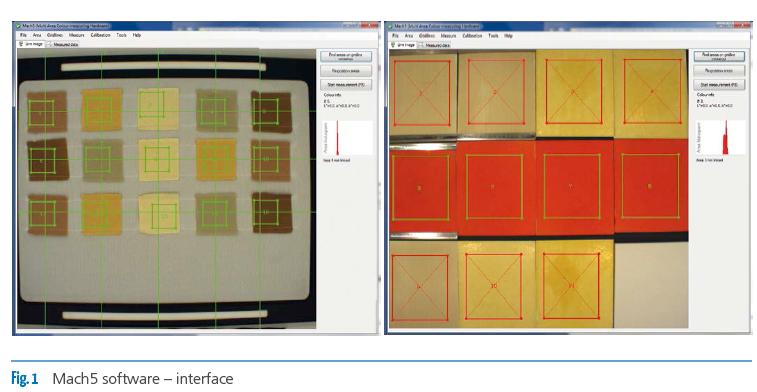

The Mach5 software is designed with a user-friendly interface (Fig. 1). Automatic warnings help the user to avoid errors, and the software helps the user to position the measurement locations. Measurement locations can be stored for future use.

Dishwash Testing & Sub Areas

Dishwash tile testing adds another problem, stains in dishwashers are not removed evenly during the washing process. Dishwash test material is often a small plate with a size of 120 mm by 100 mm. When measured with a spectrophotometer with a 9mm or even 20 mm opening, only a small area is measured and averaged and the results will vary largely depending where exactly is measured. So apart from color change (stain removal)

how and where the stain is removed is lost by measuring with a spectrophotometer. Also different users may measure at different locations. And adding multiple measurements on one dishwash tile only increases the workload.

Apart from measuring the whole area, the Mach5 also automatically splits up the measurement area in various smaller sub-areas and gives the user the standard deviation of these various sub-areas which tells something about the homogeneity of the total area measured. If needed the color values of those sub areas can be used. Rectangular areas are split up in smaller rectangles and circular areas in smaller circles.

Accuracy

Cameras are normally not very good at measuring color in absolute terms, because of the fact that they only cut the visible spectrum in 3 parts (red, green & blue). Also lighting has to be kept stable and as with all color measurement instruments ambient light must be shielded. The technology in the Mach5 is upgraded (both hardware and software), so it can measure color better and it splits the spectrum in 25 parts instead of only three.

The Mach5 is slightly less accurate than a spectro (dE < 2) but the major benefit of the Mach5 over conservative spectrophotometers is the fully flexible area shape and size, and the extra information it gives. Also it can be operated by an unskilled worker and measures faster since it can measure multiple areas in one cycle. Full size images of the measured objects are saved for later assessment. The software and part of the hardware can be adapted to a specific industry to add extra functionality useful to that industry.

Barcode Reading the Coded Test Material

Traditionally, codes are hand written on test materials, so samples before and after wash can uniquely be identified and their results compared. Since the Mach5 uses a camera it can also read barcodes. Some test material suppliers have already begun to offer a barcode service to their customers. They add a barcode to the test material. The Mach5 can read that barcode at the same time it is measuring the color, uniquely identifying the product and saving the data by the code on the test material.

Customers & Markets

The first Mach5 was sold five years ago. That first customer asked us for a market specific instrument. We designed the instrument and wrote the software and together we sell it in their market. A win for both. Because of that, most customers can currently be found in the detergent industry but we are looking into expanding into other markets. The instruments have been sold worldwide. The instrument is sold as a complete turnkey system with the PC included so the instrument can easily be serviced remotely if needed.

Benefits

• Faster measurement (faster than spectrophotometer)

• Fewer human errors

• Less labor-intensive

• Direct analysis of measured data or copy to separate spreadsheet software.

• Easy to operate (low skilled workers can operate the instrument)

• Save costs/time

• Low maintenance

A short video is available on request, please contact us for more information.

Download the Mach5 specification sheet (pdf): Mach5 specifications PDF

You can find more details on the Mach5 via this link. Mach5 instrument specifications

Send us an email or contact us for more specific information via this link: Contact us for more info on the Mach5