In the last years preform and cap color quality control have made big steps. Large multinationals in the food, beverage and cosmetics industry have been pushing the level up and up, demanding higher standards and smaller tolerances from preform manufacturers.

When it comes to preforms, measuring color with a standard spectrophotometer may not be the best way to guarantee a constant high quality. Apart from the fact that operating a spectrophotometer with its many settings is not easy and asks for trained staff that may not be around 24 hours a day, positioning a small round tube for the measurement port of a spectro is often impossible to do correct. Also when data shows there is something wrong, not many parameters can be changed to correct color variations in the production process.

Measuring transmission values with a standard spectrophotometer is an even a bigger challenge. Another reason is that the color granulate is carefully checked by the supplier and the blow molding process has very little effect on the color as in shifts of green, blue, yellow or red, or a* or b* shifts when only one colorant is used. The main change in preform color is in how much color is added, changing the L* value or transmission % by tuning the dosing system.

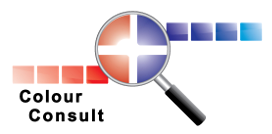

Image1: Semi transparent preforms.

Image 1 above, shows a set of semi transparent preforms where more and more colorant is added in the startup process in order to get the correct preform, its not the color that changes its the L* value or transmission value.

And although colored, semi transparent preforms as in image 1 may be checked by the human eye, its far from ideal. People are different and so are their eyes and with that their perception of color. What one person judges as correct another may not. That is to say if the people are even trained to see small differences, leaving the quality control process prone to human error and claims by customers. For example, many may see the difference of the first few preforms on the left, but the darker, more opaque preforms become, the more difficult it is for humans to see differences.

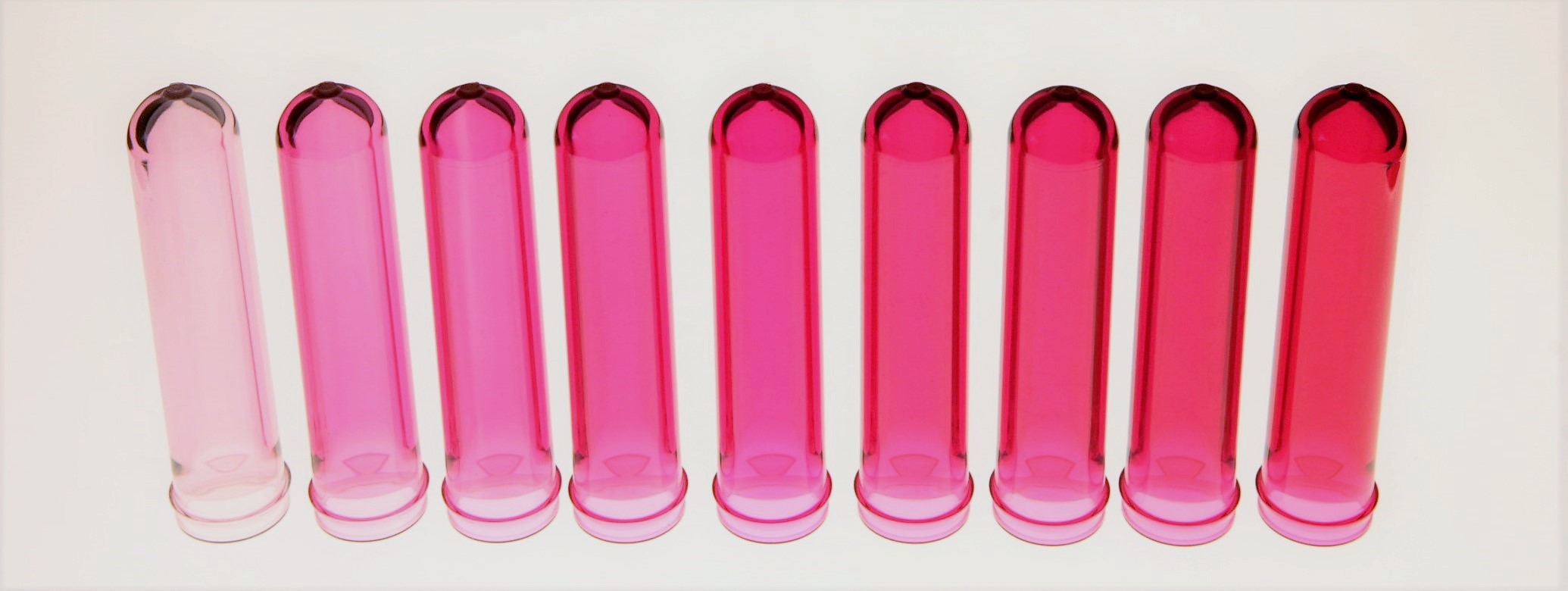

Image2: Opaque low transmission Preforms

Image 2 above shows a set of preforms that are more opaque and differences between good and not good can not be seen by the human eye anymore. Also simple tools like flashlights don’t work here anymore. For instance of the two red preforms in the image, one is good the other not hence on the outside they look identical.

The P1 preform transmission instrument was specifically designed for the preform industry. It measures accurately how much light passes through a preform, where 0% transmission means no light passes through the preform or cap and 100% transmission means all light is received (so no preform present). This instrument gives operators and quality control professionals an easy to use tool to guarantee a constant and high quality product.

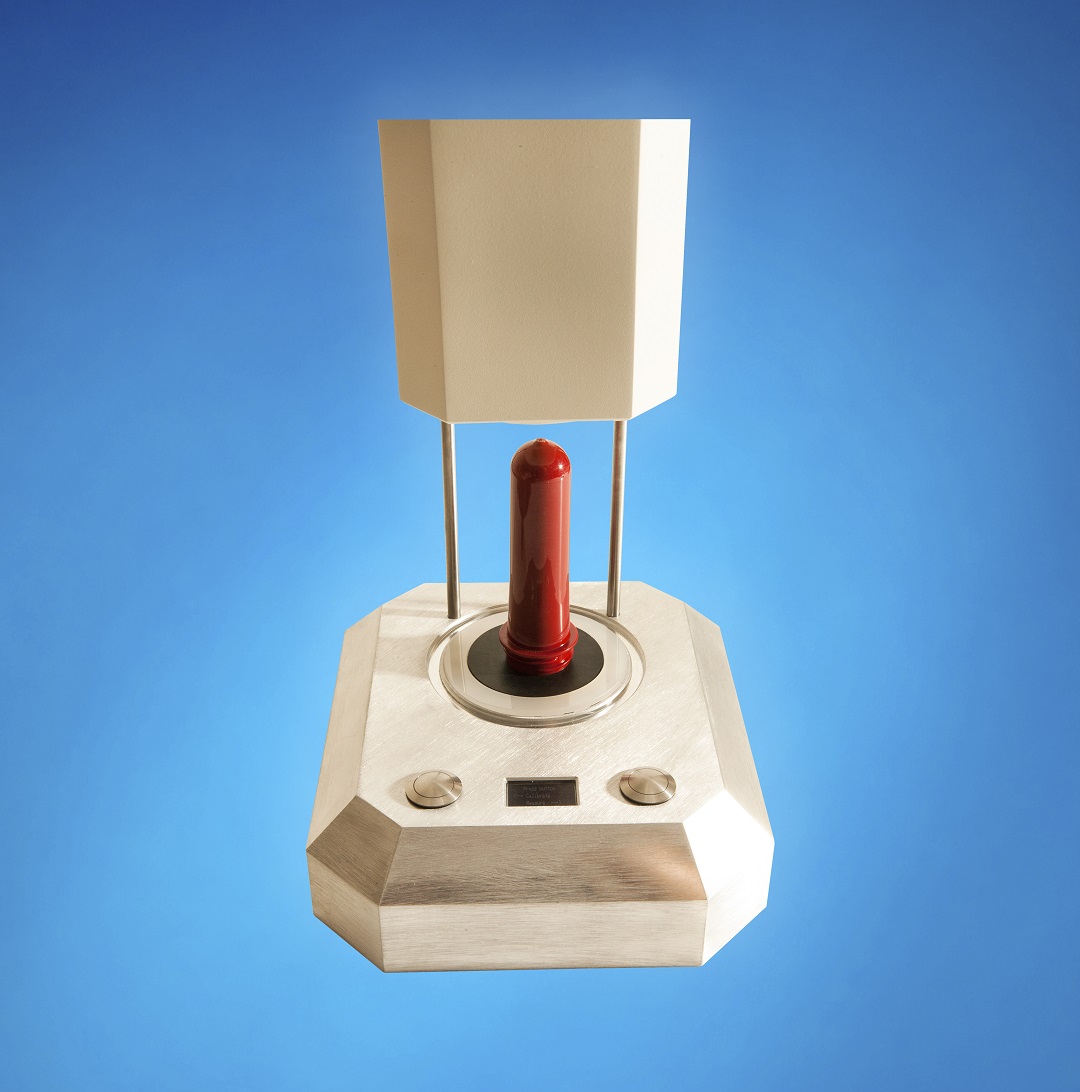

image3: P1 instrument

Opposite of a standard spectrophotometer, the preform can be placed very easily in the P1 instrument. See image 3, where the red preform is positioned in the middle of the instrument. The instrument can work stand alone or can be connected via ethernet to a company network to log measurements.

It has been designed to keep operating errors to a minimum. It has only 2 buttons and the reflection chamber has guides so it will be positioned in the same way every time.

The instrument is designed so it gets more accurate the more opaque a preform is exactly there where the human eye has trouble distinguishing L* values.

Small changes in transmission values are detected in an early stage, minimizing waste and valuable production time. Alternatively the instrument can be used to detect variations in transmission values due to preform position in the mold.

For more information visit:

www.colourconsult.nl/products/p1-transmission-instrument/

or contact:

Mr. ing. B. Hotting

Bhotting@ColourConsult.nl

Phone: +31 251 22 47 41